The best Side of powder packaging machines

The best Side of powder packaging machines

Blog Article

By including codes towards the sauce containers, organizations can boost their operational effectiveness, reduce errors, and assure that their sauce products satisfy higher-finish safety and high quality expectations.

Are you presently prepared to elevate your packaging functions to another amount? Learn the chances with our array of chopping-edge granule filling alternatives. Get hold of us these days to learn more!

A stick pack machine performs almost much like a vertical kind fill sealing machine. A wheel of your movie is Reduce and adjusted into several stick packs, the pouches are then stuffed with the specified item and sealed by using a pace of packing and filling about eighty pouches for each lane.

All of our machines are created of top of the range components, it contains 2T welding then milling integrated molding body, Japanese 20CrMnTi CNC precision machining cam , four-axis CNC machining clamp and aviation aluminum engraving and milling vacuum chamber, which make sure from the extensive everyday living cycle of our machine.

It’s vital to keep up creation dependability to fulfil quantity commitments continuously by means of preventive measures.

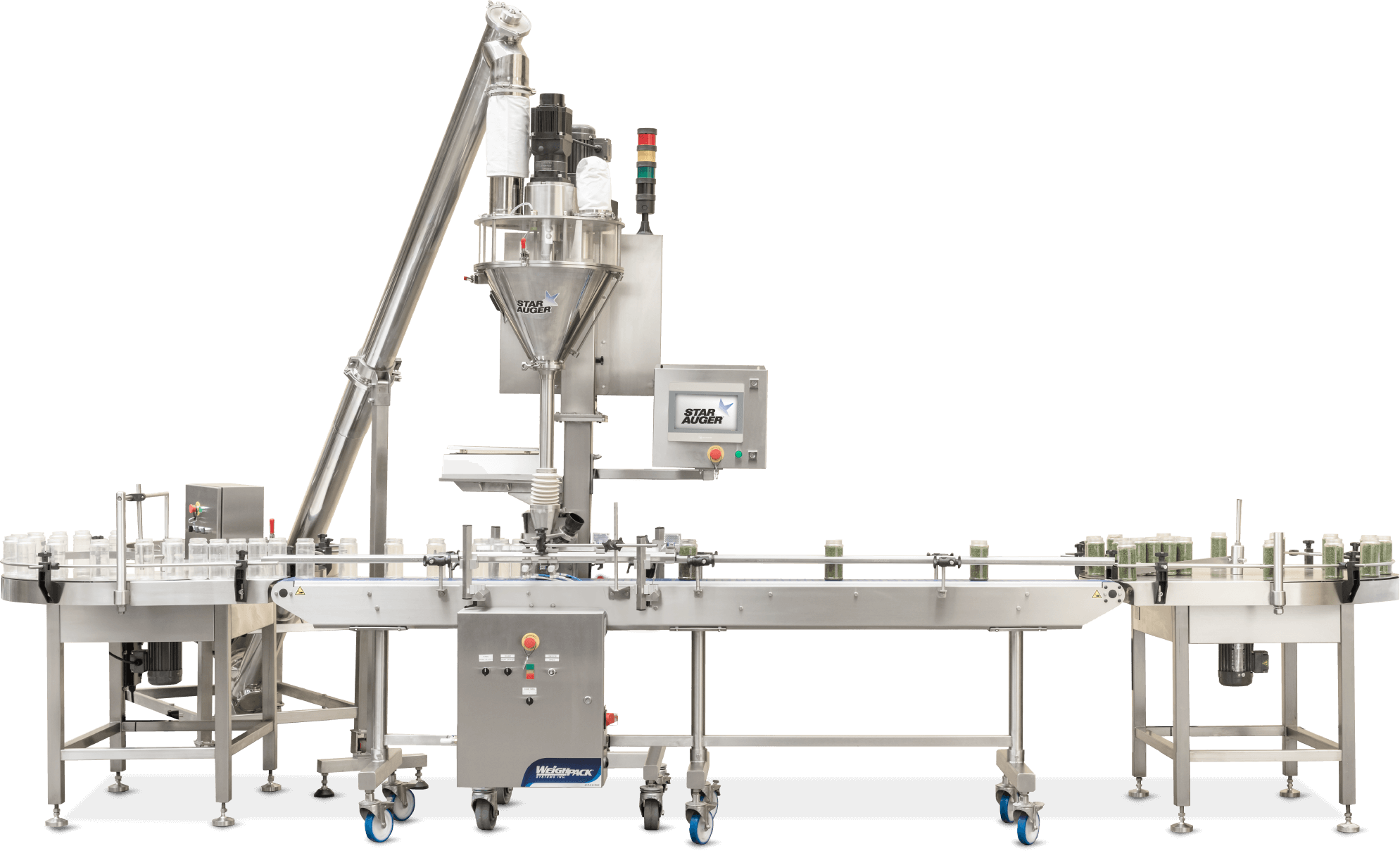

Many businesses desire working with automated can packaging machines to operate the whole process of powder packaging into can, bottles, jars. The machine helps in filling and closing or sealing the jars following staying addressed with the material.

The automated sauce labeling machines feature sensors that make certain of really specific label placement.

All of our machines are made of top quality materials, it involves 2T welding then milling built-in molding frame, Japanese 20CrMnTi CNC precision machining cam , four-axis CNC machining clamp and aviation aluminum engraving and milling vacuum chamber, which be certain in the extensive existence cycle of our machine.

Granule filling machines arise as indispensable instruments in this landscape, providing precise and fast packaging answers for the myriad of granular goods. But how specifically do these machines function? Allow’s delve in to the intricate mechanics that electrical power these marvels of contemporary engineering.

Complex Division is responsible for encouraging offer solution for an array of techinical difficulty from before liquid packaging machines sale to immediately after sale time period

This machine can run long production with precision and precision, where by a sensor is liable to detect the mistake if transpired.

Capping machines are designed to cope with a variety of cap varieties, such as screw caps, snap caps, and lug caps. At Levapack, there are actually several varieties of LPE snap capper machines and LPE screw capper machines.

R&D liquid packaging machines Division is to blame for developing and studying machines to meet a lot more buyer's necessities

Within this area, We're going to explore different sorts of sauce packaging machines And exactly how they add to efficient sauce manufacturing.